Dl6wu Yagi Design Program

- Yagi Design Calculator

- Vk5dj's Yagi Calculator

- Dl6wu Yagi Design

- Yagi Antenna Calculator Dl6wu

- Vhf Yagi Calculator

- Uhf Yagi Design

- .design, which I will call the 'Linearly Polarised TPM II',. For 2 metres, I ended up going for a 2 element Yagi, using the well known DL6WU program.

- The DL6WU antenna provided a significant boost to VHF/UHF operators using DIY antenna systems. DL6WU has contributed to a number of amateur publications, but the first of his works to reach here appeared in VHF Communications (1977). In it he presented the basis of his recipe for yagi design, at a time before computer simulation was available.

10 m band are due to low solar activity, and hence the small number of possible stations, riešili v contestoch len nenáročnou anténou, CB as a vertical. In the spring we installed a 4el. oil, which lay a long time in the cellar. The original owner was happy with it (during solar maxima), We liked, however, little. One of the tasks before the next race was the aerial Reconnaissance.

Yagi Design Calculator

Download Yagi Calculator for free. Yagi Calculator is a Windows program that also runs well on Linux, Ubuntu 8.

The original antenna had a boom with a length of 4 m. Program MMANA-GAL calculated, that the frequency 28.5 MHz in free space the antenna impedance 40 -j2 ohms, profit 4,5 dBd and before-back ratio of just over 10 dB.

Based on documents G0KSC http://www.g0ksc.co.uk/sc2104s.html I did the conversion of this attractive design antenna for 10 meters band. G0KSC yagi is very easy due to the direct power supply, antenna coaxial cable with a member of adjustment. MMANA-GAL shows these parameters: impedance 50 + j3 ohmy, profit 6,2 dBd and before-back ratio of about. 20dB. Moreover, the boom is about thirty centimeters shorter.

These parameters are now much more interesting than the original antenna. Editing involves the removal betamatch-in, shorten the boom, drilled new holes for handles elements and adapting the length of elements. Modification of our yagi was difficult because, that the previous owner too shortened elements and so I had to replace the pipe end or redundancy thinner tube, to achieve the desired size. T?the dimensions are adjusted 4el.yagi antenna:

| Element | Length | Position the boom-e |

| Reflector | 5,30m | 0m |

| Žiarič | 5,14m | 1,29m |

| Dl | 4,88m | 1,78m |

| D2 | 4,66m | 3,7m |

After changing the dimensions of the antenna is subjected to the measurement antenna analyzer. The measurements were performed at app. 5m coaxial cable RG-213 of 3.5 m. To reduce the impact of the second antenna near the yagi was against it turned 90 °. Here are the results of measurements:

| Frequency | Impedance | PSV |

| 27,8 MHz | 67 + j0 | 1,35 |

| 27,9 MHz | 62 + j0 | 1,26 |

| 28,0 MHz | 59 + j0 | 1,18 |

| 28,1 MHz | 55 + j0 | 1,10 |

| 28,2 MHz | 52 + j0 | 1,06 |

| 28,3 MHz | 50 + j0 | 1,00 |

| 28,4 MHz | 48 + j0 | 1,08 |

| 28,5 MHz | 47 + j0 | 1,09 |

| 28,6 MHz | 47 + j0 | 1,09 |

| 28,7 MHz | 49 + j0 | 1,02 |

| 28,8 MHz | 50 + j0 | 1,00 |

| 28,9 MHz | 54 + j0 | 1,10 |

The imaginary component of the frequency analyzer appeared under 27,6 MHz and at 29.2 MHz, which is growing rapidly with distance from the center of Gaza. The antenna is therefore likely, nasimulované parameters that are confirmed and work on 10m band.

Vk5dj's Yagi Calculator

23cm / 1296 MHz Field Day Yagi Construction

( of course you could use it at home too...)

Dl6wu Yagi Design

a 26 element conventional-style design

Yagi Antenna Calculator Dl6wu

7 July 2009

Vhf Yagi Calculator

Uhf Yagi Design

When I started building up 23cm / 1296 MHz transverter hardware, I knew that I was going to have to similtaneously make at least one antenna to suit. Since my prime intention is to use 23cm during field day activities, rather than from home, it seemed the best idea to start with the construction of a yagi that I could use for field days / outings. I did a bit of research and found that many of the designs around are for loop yagis on this band. I don't have anything against that style of construction - except - that when packing up antennas onto roof bars, the loops are likely to be deformed - if not actually damaged - during the field day transit phase. I have built many conventional yagis for VHF and UHF before, even a full size monobander for 20 metres, and developed a fair experience with this style of antenna construction. A quick Google search notified me that VK5DJ's yagi software had been updated so I quickly downloaded that and replaced the earlier version on the PC. This new version ( 2.6.2 ) has some new features including square versus round booms and better choices in element mounting formats. Running a task to design a new yagi for 1296 with 24 elements gave me a boom length of a bit under 2 metres so I added a few more elements to get a boom closer to the 2 metre length. The extra elements took the anticipated forward gain up to 18.5 dBi / 16.3 dBd with an estimated 3dB beamwidth of 24 degrees. This software uses the DL6WU concepts - somewhat dated - and there are probably other software packages around that could be used - but this one is easy to use and, from previous experience, the designs worked.

{ Mouse over any image for a larger view } Many of the 23cm antenna designs already on the web used a 15mm boom - and that would be fine for field days - but I prefer a larger boom size for permanent fixtures. I re-ran the software for both 15mm and 25mm boom tubes and it all looked reasonable. Yes, the element lengths changed with boom size but that was expected. The gain and beamwidth values stayed the same. I paid a visit to my local aluminium suppler (Apple Aluminium here in Brisbane) and fortunately they accept counter sales during part of their working hours so I was able to buy 2 x 4m lengths of 6mm aluminium rod plus 2 x 6m lengths of 15mm x 1.6mm wall square tube, with rounded corners, and a single 6m length of 25mm square tube, again 1.6mm wall and again with rounded corners. The whole lot set me back just shy of $50 and it was enough material to build at least a couple of yagis for this band and still have some left over. You and I know that you can't solder to aluminium so a bit more thought was given to the material for the driven / dipole element. I was hoping to find an easy source of 5mm or 6mm brass rod or tube and the only thing that I found was copper tube in 9.1mm (too large), 1/4' whitworth threaded brass rod and not much else. Finally I called into a welding supply place and found a couple of 3.2mm x 900mm brazing rods at $4.40 each inc GST, given the choice of the 2.5mm and 3.2mm rods available for this purpose, obviously I picked the largest diameter. Why brazing rod ?? I have made antennas for the 2 metre band from this material before. Yes, once bent it stays in that shape - but it is easy to work with and can be readily soldered to. | |

Now we get down to the controversy - how to mount the elements. Many abide by the idea of insulated elements - insulated with many different techniques, some on the top or above the top of the boom, some through the boom. By the same token, all of the yagis for this part of the spectrum made for commercial use (versus amateur use) all have uninsulated elements typically through the boom and bonded to the boom material by various methods including aluminium welding. Then comes the dis-similar and even similar metals argument - you don't have metals in contact with each other (unless brazed) whether the same or not. I wanted it simple - and quick. The other thing in the back of my mind was that IF it was damaged on a field day event, I needed to be able to repair it - and not just throw it away. One design I saw on the web used a centre punch to 'deform' the boom material adjacent to where the element passed through. A couple of quick 'punches' held the element material firm. The elements were bonded to the boom (not that they need to be) - good to my way of thinking... If the design worked as I hoped, and if I needed to, I guess I could always buy some of that aluminium brazing 'solder' and braze the elements to the boom at the exit holes - not straight away though - I needed to be able to build and then evaluate the antenna before making anything too permanent.

Ok, mounting the yagi. I didn't know exactly how heavy a 2 metre length of 15mm tube with 1.6mm wall - plus - the 25 aluminium elements and the driven element was going to weigh. Hopefully it was going to be ok to end mount. Without some research to check the exact weights, I was going to have to 'play it by ear' and hope that it was within acceptable weight limits. One thing about the DL6WU-based designs, if you have to then you can shorten it without altering any other element lengths - so if necessary, I could simply cut off some boom/elements to make it manageable. | |

The boom length calculated with the VK5DJ software was 2002mm, which included a 30mm allowance for the front and back elements to the end of a conventionally (centre) mounted yagi. Since I wanted to end mount this one, I added more to give a total boom length of 2150mm. A quick cut with a hacksaw, a touch up with a file and I was ready to start marking the 15mm square boom out with the element positions. The easy way to make the elements line up is to scribe a pencil line mid-way along one side of the boom, carefully mark the element spacings from the 'VK5DJ printout' along the scribed line. Since we are working with square material, it is somewhat easier than doing the same task with round material. The pencil line down the centre makes it easy to get the elements in a straight line The task of drilling the holes if you don't have a drill press (and a drill-press-vice) is going to be arduous. If you are likely to be doing much construction/drilling over the next few years, buy one of the cheapie drill presses around - typically about $50 or so. They will make your life a whole lot easier. While you are there, have a look for a flat vice that will sit on the working table of the drill press - simply because they will hold your 'job' steady while the holes are drilled. The aluminium rod I bought is 6mm - right ?? Sorry, no it's not. It is actually just over 6mm - but less than 6.5mm (1/4'). If you drill 1/4' holes in the boom, the elements will slop about and simply fall out. You actually need to drill 6.0mm holes and then use a 12mm (/ 1/2') tapered reamer to slowly expand the holes so that the 6mm rod is a tight fit - even if you have to end up tapping the element through the 2 boom holes with a small hammer. Also, remember that the hole will be tapered from the outside edge to the inside edge - so go slowly. The drill press plus a properly retained vice will allow you to drill holes at right angles through the boom material. Attempting the same with a hand drill will likely result in haphazard results, and while the overall performance of the antenna will not be affected, the elements will be out-of-line and it will look weird. One thing to note, depending on what material and how you intend to mount the driven element, don't drill a hole in the DE position on the boom. I used a 3.0mm drill so that I could retain the correct postioning of the DE and be able to take it out to the correct size later. All other element holes were drilled with 6.0mm high speed drill. If you are going to mount the DE on the top of the boom as I eventually did, you don't need a hole at all - but you do need to permanently mark the DE position so that you can accurately position it later.

The 4 metre length of '6mm' rod will be enough material to make the elements for this 26 element design and still leave you some if you need to replace any damaged or incorrectly-cut elements. I suggest starting from the reflector and cutting the relevant length off the rod by marking the length first, cutting outside the line so that you have about 0.5mm to 1mm extra length and then filing it down to size with a 2nd cut flat file. Once it is accurately set to length, bevel both ends with the file and place it in the reflector position on the boom (carefully using the reamer to slowly expand the hole in the boom, first one side then the other). Make sure you are using a sharp 24TPI or 32TPI hacksaw blade when cutting the rod and if you have any 'hacksaw chatter' marks on the rod/element discard that piece. When you come to insert a rod with 'chatter marks' in through the boom holes, the 'chatter-ed material' is likely to catch and not go through the holes smoothly. Check the insertion length from the printout for the reflector and that you have it inserted into the correct position before using an automatic centre-punch (or in my case a manual punch and a small ball-pein hammer) on the boom just adjacent to the element material. A quick punch and the element should be held in place. Repeat again for all of the directors, leaving the driven element (which we haven't yet created) until last. Others may cut all of the elements in one go then fit each element into the boom in one session. One tip though regardless of which way you do it : tick off each element length on the list as you finish it so that you know what length the next one has to be. My version typically only had one punch mark per side per element but you have to remember that I want to be able to change elements if one gets damaged - you should probably multiple-punch each element for longetivity..

The secret to success with this type of construction is 'take your time'. If you ream out the holes so that they are too big because you have hurried then you have two choices - start again with a new boom piece - or go to the hardware, buy a couple of the aluminium brazing sticks (Bunnings tool section - 2 for about $10), braze up the holes and re-drill and re-ream. Given that the 15mm boom tube was about $5 + 10% GST per 6m length, the new boom tube is the better option. The second thing is accuracy - keep all dimensions as accurate as possible. Measure the boom tube dimension to see that it is in fact 15.0mm (mine was), make sure each element is the correct length (mine, after filing, would have been within 0.2mm).

How long should the the whole marking, drilling and cutting process take ? Well, the task up to this point (i.e. all elements except the DE mounted ) was just over 2 hours. If you are better organised than I was, it could be somewhat less. | |

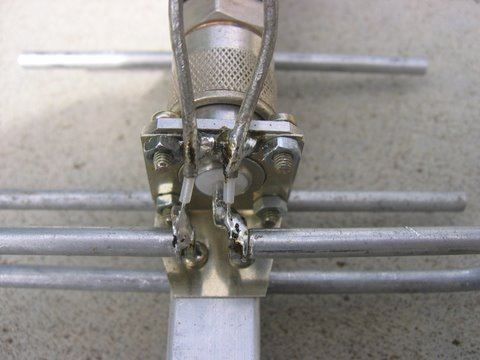

Now for what I consider the hardest part : the driven element (DE). In this design, the driven element is a folded dipole fed via a 4:1 coax balun. The DE is 3.2mm brazing rod and is insulated from the boom (to prevent dissimilar metal issues). According to the printout, the full length of the DE material is 232mm and since we are starting with a 900m length of rod, that means we can have a few chances at getting it correct. The printout also specifies exactly how long the dimensions of each part (straight, curve etc) of the folded dipole should be and it is in our best interest to make it as accurately as possible. If you have it pass through the boom, even though insulated from it, you can just make the entire dipole assembly pass it through the two boom holes, not easily - but it will go through. Of course, you can bend up one half of the folded dipole and then just pass the un-bent side through the DE hole, then bend the second side ! With the brazing rod, it is quite still to bend so it is easier to make up the whole assembly so you can check the dimension tip - to - tip. From the table you see below, the bend diameter of the folded dipole is 25mm - a common enough value for wooden broomstick handles and other utility devices around the home. Extracting the following details :

Now as to insulating materials to suit the 3.2mm diameter brazing rod : The simplest method is to use some heatshrink (black preferred) and shrink a couple of layers at the centre of the folded dipole material. Make the section about 30mm long and trim it up afterwards with a sharp utility knife so that it only extends about 4mm to 5mm each side of the boom tube (i.e. 23 to 25mm long overall). The final size of the DE hole in the boom tube (if used) is determined by the overall size of the layers of heatshrink once finished off. In my case, the DE with 2 layers of heatshrink came out at 5.2mm. It has to be a snug (but not overly-tight) fit through the boom holes. A dab of glue from a hot glue gun (preferred) -or- a small black cable nylon cable tie on each side should hold the DE in place if it is fed through the boom - to be done later.... If mounting on top of the boom, the DE is held in place by an aluminium saddle and hot glue is not required. Use a 25mm former (tube, broomstick etc..) to form the dipole ends and make sure that the ends are brought back to give the correct tip-to-tip dimension as well as the specified gap value of 15mm, and is accurately centred on the boom. | |

Now we must not forget the 4: 1 balun construction because that is what we need, along with the coaxial connection, to finish the antenna. Since we are using this at 1300-odd MHz, you MUST use an N-series coax connector. You CANNOT use a PL259 / SO239 under any circumstances. You could get away with a BNC but that would be a variation from normal practice for these frequencies. You have to remember that only N-series connectors are available for the low loss coaxial cables like LMR-400, LMR-600 and the low loss heliaxes like LDF-4/50 and its larger cousins - and this is the type of cable you should be using for feedline at this frequency.. I have seen photos on various web sites using different techniques and all providing the same outcome - a 4:1 balun at 1300MHz. Any of those (where suitable) can be substituted for my technique. If you cannot find an N-female connector exactly the same as the one I used (or a very similar style), you will have to wing it and just follow the general trends shown here. Altronics part P0454 - panel mount N female connector The balun can be any suitable coax cable appropriately rated for the frequency and the power level involved. Please note that each coax has it's own velocity factor (Vf) and that value has to be used to calculate the final length of coax used in a balun for use at any specific frequency/band. For very low power, you could use one of the very small poly or PTFE 50 ohm coaxes (eg RG174 or RG316) or even a PCB-style tuned line, for low to mid power levels even a good foam coax like RG58AU or RFI's 9006 Cellfoil would suffice. For high power, a lot more care has to be taken in selecting a suitable cable. I have decided to use the RFI 9006 cable - which has a Vf of 0.70 - hence the line 'A half wave 4:1 balun uses 0.70 velocity factor coax and is 81 mm long plus leads' in the printout. | |

| As you may have noticed, the driven element (DE) is the one purely variable entity in this whole design. You could make it as a straight dipole or a folded dipole. The matching arrangement is up to you and provided the method is appropriate, and the resulting SWR is low, the antenna should perform much as designed. | |

Details of my folded dipole construction : Cut the 232mm specified length off the 3.2mm brazing rod. Lie it along a ruler (steel style preferred) and mark of the centre point at 116mm, then the 35, 54 and 74mm from each end using a thin tip permanent marker. Using your 25mm former, use the 54mm marker and bend the rod each side of the former. I found that it was easier to use multigrips to grip the short (54mm) end and thus end up with a reasonably round curve. If it isn't perfect, it shouldn't really matter. It was at this stage that I added the two layers of heatshrink. I marked the positions 12.5mm each side of centre of the rod, cut two 25mm pieces of black 6mm heatshrink, centred it between the two extra marks and shrunk first one piece then the other over it. Note : if you are going to feed it through the boom, measure the diameter with a micrometer and drill the size below then ream it out so the heatshrink is snug fit through the boom holes. If you do, it should look like this : The second end of the dipole is then bent using the same 25mm former as before. You can still feed it through the boom by bending one end slightly and then bending it back into line afterwards. I decided that I would mount it on the top of the boom so that it would be a better match-up with the N female connector so a saddle was fabricated from a strip of thin gauge aluminium and pop-riveted to the top of the boom with 1/8' aluminium rivets - as per the photos. A 25mm x 50 mm right angle bracket was fabricated so each side was 25mm square and a suitable hole was made to pass the threaded end of the N female connector. I happened to have some 25mm square aluminium tube so I simply took a 25mm slice off the end, cut away 2 sides with a hacksaw to leave a right-angled piece. In some ways this might be better than a bent piece of flat as the material will not have any tendency to 'give'/straighten if pressure is applied (ie. coax accidentally tugged) This was then pre-drilled with 2 mounting holes and matching holes drilled in the 'underside' of the boom. The N connector was removed and the L bracket pop-riveted to the boom The connector was replaced and the dipole end matched up in spacing from the boom and at the very end of the 54mm bottom length. Time to warm up the soldering iron. From your selected coax cable for the 1/2 wave balun, cut off one end and tin the outer braid. The 9006 cable used here has a solid copper inner conductor with a foam dielectric (Vf = 0.7) and a wound aluminium shield as well as the braid. trim off the dielectric and shield, measure along about 75mm and remove the outer sheath. I measured, then re-measured so that by the time I had my cable finished at both ends, the end-of-dielectric to end-of-dielectric length was exactly 81mm. The cable was formed into a U shape and a piece of heatshrink slipped over from the open end to hold it in shape. The braids were then soldered together. The inner conductor ends were trimmed to about 4mm and the balun was soldered to the dipole ends, along with the protruding centre pin of the N connector on one side. The next step was to tin the earthing lug on the N connector and run a piece of thick braid across from it to the common braid connection of the balun. Final step was to add a black nylon tie at the bottom of the balun loop to provide some rigidity. Needless to say, the feed assembly will be waterproofed after testing. Voila, all completed. | |

This photo was taken during the setup for the 2009 Spring VHF/UHF Field Day here in Australia showing the yagi mounted above the hinged 11 element 70cm yagi. This is a close-up of the actual mounting section of the photo : Note that the bracket assembly was screw & wingnut-ed to the boom for easy removal for transit. The black steel brackets were actually scrounged from a couple of on-hand replacement screen pneumatic door closer packs that didn't actually require the brackets being changed but almost any other strong 90 degree brackets could be used. These were triple pop-riveted to the riser pieces. The tubing used for the vertical and horizontal parts of the support bracket was 25mm square aluminium and the matching 90 degree corners just the readily-available ones from the hardware as used for making up tubular framing for tables, shelves etc... The u-bolt and v-block were retained by flat washers & wingnuts on the 5/16' threaded section ( just visible below the cross piece ). This shows the antenna up in the air and gives a better view of the wingnuts on the u-bolt. The whip & base on the short cross-arm in the foreground is used on 6m FM and / or 2m FM. The yagi was used quite successfully during this field day event and a number of contacts were made on 1296 MHz giving valuable points and grid square multipliers. The 10 metre section of LMR-400 low loss coax with N connectors at each end gives a calculated loss of about 1dB at 1300 MHz and has been reserved specifically for use with this antenna for field days. The I.F. driver transceiver ( a Kenwood TR751A 2m multimode ) plus 23cm transverter ( diecast box with heatsink on top ) as set up for the field day : With the approximate 20+ watts out of the transverter, using this yagi should provide about 600 watts ERP or 1 Kw EIRP !!! Dec 2009 : I have only recently bought a 500MHz - 2GHz directional coupler that will allow me to accurately make forward/reverse power measurements but I haven't yet setup the gear again to do any on this specific antenna. | |

This was the design criteria used for this antenna, per a cut-and-paste from the software:

Yagi design frequency =1296.00 MHz REFLECTOR RADIATOR DIRECTORS COMMENTS Spacings measured centre to centre from previous element Boom position is the mounting point for each element as measured from the rear of the boom and includes the 30 mm overhang.The total boom length is 2002 mm including two overhangs of 30 mm The beam's estimated 3dB beamwidth is 24 deg A half wave 4:1 balun uses 0.70 velocity factor coax and is 81 mm long plus leads If the folded dipole is considered as a flat plane (see ARRL Antenna Handbook) then its resonant frequency is less than the flat plane algorithm's range of 10:1 |